Seamless knitting is revolutionizing how we design and manufacture clothing. By eliminating traditional cutting and sewing processes, this innovative technology creates garments that are more comfortable, durable, and sustainable. From yoga pants to high-performance sportswear, seamless knitting is changing the game for brands and consumers alike.

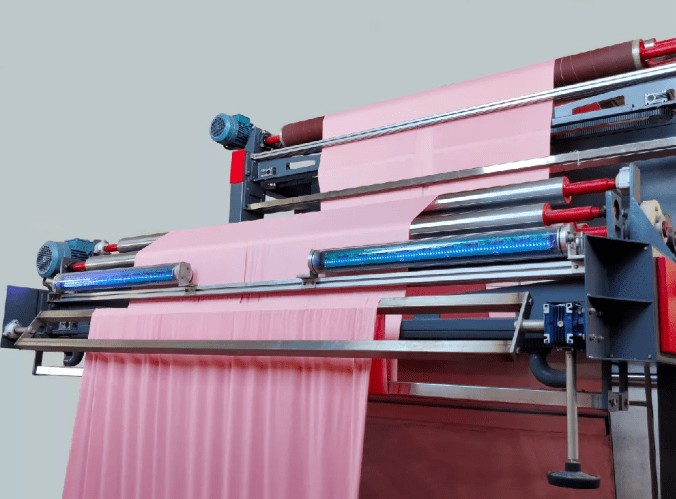

Seamless knitting uses advanced computerized machines to produce complete garments in one continuous process. Unlike traditional methods that require multiple fabric pieces to be cut and sewn together, seamless knitting creates entire garments with:

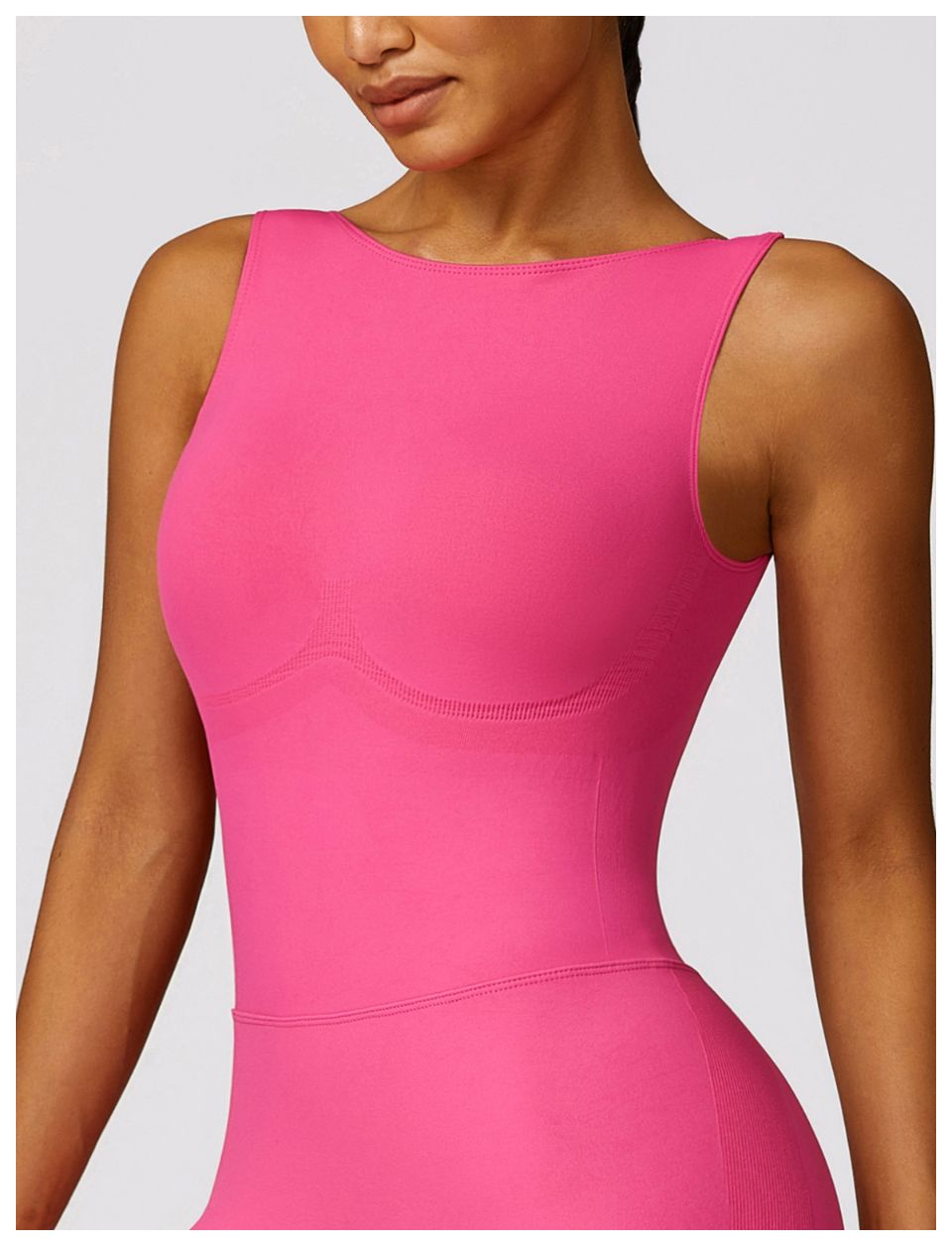

This technology is particularly valuable for activewear, where comfort and performance are critical.

The most advanced approach creates complete garments in one piece. Using machines like Shima Seiki's WHOLEGARMENT® system, manufacturers can produce items like high-end yoga pants and seamless bras without any stitching. Lululemon's popular Align leggings showcase this technology's benefits.

A more cost-effective option focuses seamless technology only on high-stress areas like waistbands and cuffs, while using traditional methods elsewhere. German STOLL's CMS 530 machines excel at this hybrid approach, ideal for performance sportswear that needs targeted comfort zones.

For waterproof outdoor gear, heat bonding uses ultrasonic welding to fuse fabrics without stitches. Swiss-made Roaches machines create durable, watertight seams perfect for jackets and technical apparel from brands like Arc'teryx.

Leading sportswear companies are adopting seamless knitting for five compelling reasons:

From the yoga studio to the ski slope, seamless technology is making its mark:

While the benefits are clear, adopting seamless knitting presents some hurdles:

High Equipment Costs - Solutions include partnering with specialized manufacturers or exploring equipment leasing options.

Design Complexity - New software tools like CLO 3D help designers visualize seamless garments before production.

Material Limitations - Innovations like PrimaLoft® Bio blends and bio-based elastanes are expanding material options.

Looking ahead, three exciting developments are emerging:

For brands considering the transition:

The shift to seamless knitting represents more than just a manufacturing change - it's a fundamental improvement in how we create clothing for active lifestyles. As technology advances and becomes more accessible, we can expect to see seamless construction become the new standard in performance apparel.

© 2024 [Company Name] Textile Innovation Center

Data source: ISO 6330, Adidas technical report, MIT Textile Laboratory

Make an appointment for consultation now → Click to jump