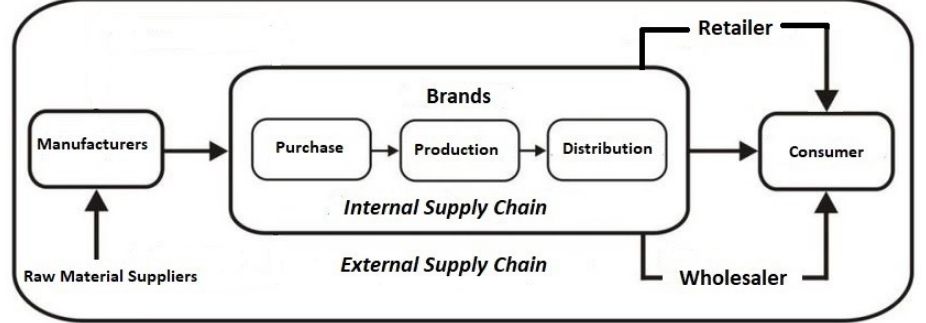

Diving into the world of Active Wear Production, we uncover a complex web of supply chain dynamics. At its core, there are intricate processes from raw material sourcing to final product delivery, including collaborations with sweatsuit vendor wholesale. Key components include textile selection, manufacturing efficiency, and distribution logistics. These elements, each a gear in the larger mechanism, work in unison to satisfy market demands. The journey of a single active wear item reflects a symphony of coordinated efforts, revealing the industry's commitment to innovation and quality.

In active wear production, the supply network begins with raw material acquisition. Fiber providers supply textiles to factories, involving complex logistics operations.

Subsequently, fabricators transform these materials into usable fabrics, essential for garment creation. This network relies heavily on efficient transportation and coordination, ensuring timely delivery.

The production stages in active wear production encompass several critical steps. Initially, design teams formulate concepts, using CAD for precision.

Then, pattern makers and cutters shape fabrics to specifications. Assemblers stitch these pieces, while finishers add final touches, like zippers or logos, crucial for market appeal.

Logistics management in active wear production is multifaceted. It starts with coordinating material shipments to production facilities. Then, overseeing the distribution of finished goods to warehouses plays a key role. This phase also includes managing inventory levels and ensuring efficient product flow to retailers or direct consumers.

Quality control in active wear production is rigorous. It begins with inspecting raw materials for defects. During manufacturing, spot checks ascertain adherence to design specs.

Post-production, garments undergo stress tests, checking for durability and performance under various conditions, a vital step for brand reputation.

Vendor selection in active wear production demands careful consideration. Factors include manufacturing capabilities, cost-effectiveness, and ethical practices.

Producers often evaluate potential vendors based on past performance and compliance with industry standards. Building strong relationships with reliable clothing suppliers is crucial for sustained quality and supply chain stability.

In active wear production, synthetic fibers like Polyester and Nylon dominate due to their durability. These materials, resistant to shrinking and stretching, maintain garment shape. Quick-drying properties, essential for sportswear, are inherent in synthetics. They also offer high color retention, keeping active wear visually appealing over time.

Cotton, a primary natural fabric in active wear, offers unmatched comfort. Its breathability is ideal for low-intensity workouts, reducing skin irritation.

However, its moisture absorption can be a drawback for high-intensity activities. Bamboo fabric, another natural choice, provides softness and eco-friendly benefits, gaining popularity in sustainable active wear lines.

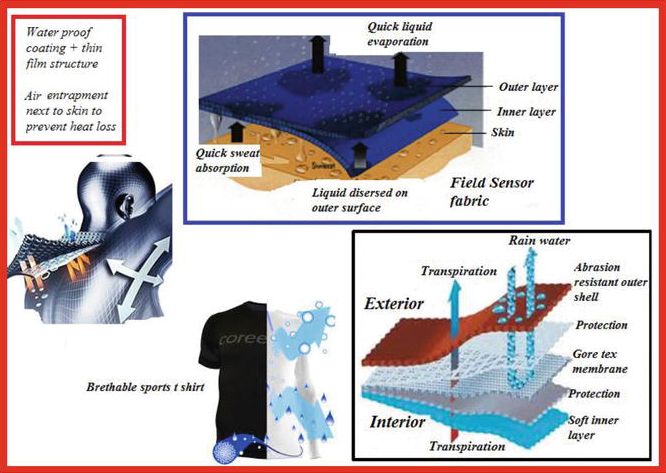

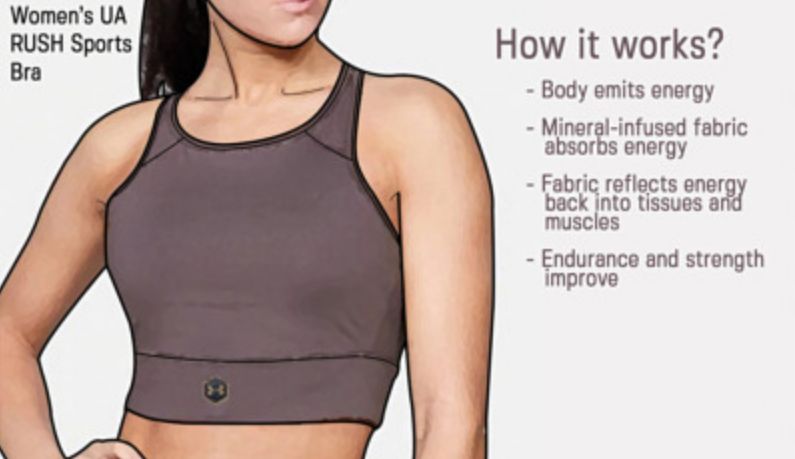

Performance textiles are engineered for specific active wear functions. Features like moisture-wicking, temperature regulation, and UV protection are common.

These fabrics often incorporate antimicrobial treatments, preventing odor in workout clothes. Such textiles enhance athlete performance by managing body temperature and comfort during physical activities.

Blended materials combine the best attributes of synthetic and natural fabrics. For instance, cotton-polyester blends in active wear balance comfort and durability.

These blends provide the softness of cotton with the strength and moisture-wicking properties of synthetics, ideal for versatile sportswear.

Technical fabrics in active wear, like Gore-Tex and Spandex, are pivotal for enhanced functionality. Gore-Tex offers waterproof yet breathable properties, crucial for outdoor gear. Spandex, with its exceptional elasticity, contributes to the fit and flexibility of sports apparel, essential for a wide range of movements.

In active wear production, an important element is the extensive evaluation of the different suppliers. This is based on certain productions capacities, delivery schedules, and sustainability practices among others.

Sourcing partners contribute towards sustaining a supply chain material to the related similar quality standards of the final product for better performance.

Material checks in the production of active wear include tensile strength, stretchability and colour retaining. The fabric is submitted to a number of tests that will qualify whether it can withstand the pressure of an active wear product, which will be directly reflected into its durability and comfort enjoyed by users of such products.

Another step which must be done is negotiation of the costs with the material suppliers. Active wear producers want to find a compromise between this and the quality of materials used to produce, as it influences the market price on final product and profit margins.

Global sourcing in active wear production requires navigating complex supply chains. Accessing diverse materials from international markets ensures quality and innovation in fabric selections, essential for competitive active wear lines.

Quality checks are the integral part of active wear production. One needs to continuously ensure uniformity, resilience and performance standards of all materials to make sure the final products will meet high support expectations of people who wear active.

When making active wear, choosing the right maker is key. You check their history, how good their fabrics are, and if they work fairly. Picking great makers means your active wear will be top-notch.

It's important to know how much a maker can produce. They should handle big orders well and keep up the quality. This means they can meet buyers' needs and make lots of clothes without trouble.

Makers of active wear need to really know their stuff. They should be experts in working with different fabrics and making clothes that perform well. This know-how means better and more advanced active wear for customers.

Following rules is super important in making active wear. Makers must stick to labor and environment laws. Doing things right keeps problems away and means the clothes are made in a good way for everyone.

Making active wear well but at a good cost is a tricky balance. Makers work to keep costs down but still make great clothes. This helps make the active wear affordable and still of high quality for everyone.

The journey of active wear production begins with brainstorming. Here, creative minds come together, drafting and shaping new ideas. This step is about dreaming up styles that not only look good but are also right for action. It's where fun designs meet practical needs, leading to cool and useful active wear.

Next in active wear production is making a prototype. This is about turning sketches into something real. It's the first version of the design and is really important. It helps to see if the design works or if it needs changes.

Picking the right materials is a big part of making active wear. The goal is to find fabrics that are strong, comfortable, and look good. Each fabric needs to be just right for the activity it's meant for. This step makes sure the clothes are great for use.

After the design is made, it's time to test it. This means checking if the clothes are comfortable and fit well and are strong. This step is super important to make sure the active wear will be liked by the people who wear it.

This step in active wear production is tweaking the design. After testing, small changes are made to improve it. This might happen several times to get everything perfect. It's all about making the active wear the best it can be.

In active wear prod., ISO norms guide. Fabric quality, durability, and safety; these are paramount. Tests validate material performance, stretching beyond usual limits. Auditors scrutinize, ensuring ISO adherence. Result? Superior active wear is resilient in diverse conditions.

Testing fabrics, a core stage in active wear creation. Strength, elasticity, color retention are all under scrutiny. Rigorous assessments lead to exceptional textiles. These textiles are the heart of durable active wear. Endurance under stress is a testament to their quality.

Audits, a vital cog in active wear manufacturing. They dissect production processes, seeking flaws. Regular audits elevate product standards. This continuous improvement cycle benefits consumers. Quality assurance is a relentless pursuit in active wear prod.

Metrics define active wear production's success. Durability, comfort, fit; key indicators. Monitoring these metrics is a constant endeavor. They shape the production, tailoring excellence. The outcome: active wear that excels in performance.

Final inspections are the last defense in quality control. Here, active wear faces stringent checks. Any flaws detected, rectified promptly. This stage is crucial for customer satisfaction. Ensuring every piece meets the highest quality standards.

|

Quality Aspect |

ISO Compliance |

Fabric Testing |

Production Audits |

Quality Metrics |

Final Inspection |

Additional Information |

|

Standard Compliance |

ISO 9001, ISO 14001 |

ASTM, AATCC, EN, JIS, GB |

Adherence to ISO and other standards |

Compliance with industry standards |

Ensures compliance with all standards |

Essential for international market export |

|

Fabric Quality |

Guides quality management |

Strength, colorfastness, shrinkage testing |

Audits include fabric quality checks |

Fiber quality, durability properties |

Visual inspection for fabric defects |

Crucial for garment durability and performance |

|

Stitching Quality |

Ensures consistent quality |

Not directly applicable |

Checks for even, secure stitching |

Broken stitches, misaligned seams |

Inspects for stitching errors, seam puckering |

Affects garment durability and appearance |

|

Colorfastness |

Sets management standards |

Tests for color retention |

Audits include colorfastness assessment |

Measures color retention under various conditions |

Checks for fading, print |

|

Table on Quality Assurance In Active Wear Production: What Are The Standards!

In active wear production, inventory management is key. Stock levels constantly monitored, ensuring availability. Efficient storage systems are vital. This balances supply and demand. Ready stock speeds up the distribution process. The result is seamless transition from factory to retail.

Planning distribution is a strategic phase. Route optimization enhances efficiency. Coordinated efforts link factory and markets. Timely delivery is a primary goal. This ensures active wear reaches retailers swiftly. Effective planning equals customer satisfaction.

Coordination in shipping is crucial for active wear. Seamless sync between production and transport is ensured. This minimizes delays. Regular updates keep the process transparent, and ensure the safe transit of goods. Coordination leads to timely arrivals at retail outlets.

Security during transit is a top priority. Active wear protected against loss, damage. Advanced tracking systems employed. These ensure real-time monitoring. Secure transit maintains product integrity. Peace of mind for manufacturers and retailers alike.

Timely delivery is essential in active wear production. Schedules strictly adhered to. This avoids stock shortages at retail. Rapid delivery maintains market relevance. It meets consumer demand efficiently. On-time delivery is a mark of excellence in logistics.

In active wear, eco-friendly materials gain ground. Recycled fabrics are becoming a norm. These materials reduce environmental impact. Sustainable textiles redefine product quality. Their use signifies a shift towards eco-responsibility in production.

Reducing waste is a pivotal goal in active wear production. Efficient use of materials is key. Scraps repurposed, minimizing waste. This approach reflects environmental consciousness. Resulting in less landfill contribution is a step towards sustainability.

Green manufacturing processes are evolving. They focus on reducing harmful emissions. Utilizing renewable energy sources is crucial. This approach lessens the ecological footprint. It marks a progressive shift in active wear production.

Sourcing materials sustainably is a vital practice. It ensures environmental and ethical standards are met. Partnerships with responsible suppliers are formed. This enhances the overall sustainability of the production chain. It’s a commitment to ethical practices in active wear production.

Energy efficiency is a cornerstone in sustainable production. Using less energy reduces carbon emissions. It also cuts operational costs. Efficient machinery and lighting systems are adopted. These practices reflect a commitment to sustainability in active wear production.

In active wear production, market research is essential. It identifies customer preferences. These insights shape product development. Adapting to market needs is crucial. This responsiveness ensures relevance in a competitive landscape.

Integrating customer feedback is key to satisfying demands. It guides improvements in active wear. This feedback loop is vital for quality enhancement. It ensures products meet customer expectations. The result is a loyal, satisfied customer base.

Trend analysis plays a pivotal role. It forecasts upcoming fashion shifts. Active wear producers adapt accordingly. Staying ahead of trends keeps brands relevant. This strategic foresight is critical in a dynamic market.

Flexibility in supply chain management is crucial. It allows quick adaptation to market changes. Efficient production and distribution are optimized. This agility meets fluctuating demands effectively. A flexible supply chain is a competitive advantage in active wear.

Accurate demand forecasting is essential. It prevents overproduction and stock shortages. Data-driven predictions guide inventory management.

This strategic planning ensures supply meets demand efficiently. In active wear production, it's key to customer satisfaction and business sustainability.

In a nutshell, the manufacturing chain of supply for active wear is a well-choreographed tune of materials, technology, and strategies. From sourcing of raw material to slick logistics, every aspect epitomizes industrialized genius. Stakeholders looking forward to maneuvering through this dynamic sector ought to appreciate this fact. Dive deeper into the world of active wear production at SANSANSPORTS.